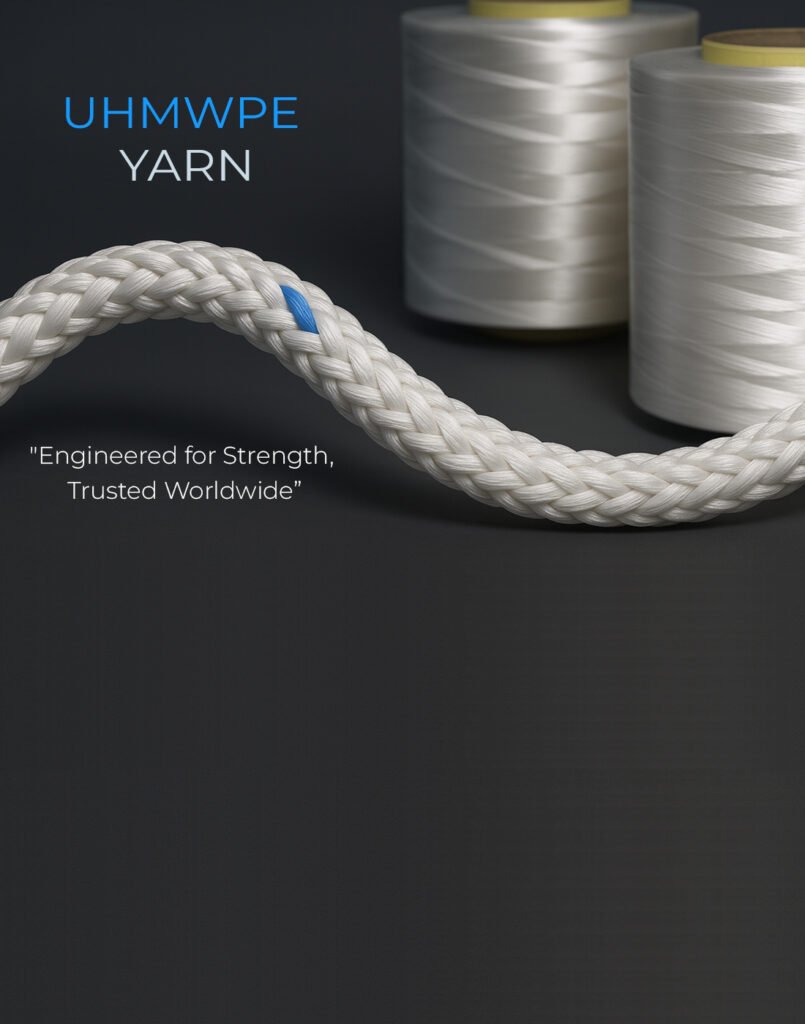

Ultra-High Molecular Weight Polyethylene (UHMWPE) yarn is a high-performance yarn recognized for its exceptional mechanical properties and versatility. With a strength-to-weight ratio up to 15 times greater than steel, it outperforms traditional synthetic fibres like polyester, nylon, and aramid across multiple demanding industries.

UHMWPE is produced by aligning ultra-long polyethylene molecular chains in the same orientation, resulting in a material with tenacity ranging from 33 to 45 grams/denier (g/d) — making it one of the strongest synthetic fibres available. UHMWPE yarn also exhibits low elongation, high abrasion resistance, chemical stability, and natural buoyancy, making it ideal for both dry and wet environments.

Its resistance to UV rays, moisture, and mold makes UHMWPE a reliable choice for outdoor, maritime, and industrial use. The combination of light weight, exceptional strength, and long-lasting durability helps manufacturers reduce product weight, increase safety margins, and extend service life.

Whether you’re manufacturing bulletproof vests, ballistic components, surgical threads, or next-generation lifting slings, Techtextile’s UHMWPE yarn, in collaboration with Webtex Taiwan, offers a future-ready solution backed by technical support, quality assurance, and regional agility.

Up to 15x stronger than steel. Built for performance

across defence, medical, marine, and industrial sectors.

Ultra-High Molecular Weight Polyethylene (UHMWPE) yarn is a high-performance yarn recognized for its exceptional mechanical properties and versatility. With a strength-to-weight ratio up to 15 times greater than steel, it outperforms traditional synthetic fibres like polyester, nylon, and aramid across multiple demanding industries.

UHMWPE is produced by aligning ultra-long polyethylene molecular chains in the same orientation, resulting in a material with tenacity ranging from 33 to 45 grams/denier (G/d) — making it one of the strongest synthetic fibres available. UHMWPE yarn also exhibits low elongation, high abrasion resistance, chemical stability, and natural buoyancy, making it ideal for both dry and wet environments.

Its resistance to UV rays, moisture, and Mold makes UHMWPE a reliable choice for outdoor, maritime, and industrial use. The combination of light weight, exceptional strength, and long-lasting durability helps manufacturers reduce product weight, increase safety margins, and extend service life.

Whether you’re manufacturing bulletproof vests, ballistic components, surgical threads, or next-generation lifting slings, Techtextile’s UHMWPE yarn, in collaboration with Webtex Taiwan, offers a future-ready solution backed by technical support, quality assurance, and regional agility.

Up to 15x stronger than steel. Built for performance

across defence, medical, marine, and industrial sectors.

Ultra-High Molecular Weight Polyethylene (UHMWPE) yarn is a high-performance yarn recognized for its exceptional mechanical properties and versatility. With a strength-to-weight ratio up to 15 times greater than steel, it outperforms traditional synthetic fibres like polyester, nylon, and aramid across multiple demanding industries.

UHMWPE is produced by aligning ultra-long polyethylene molecular chains in the same orientation, resulting in a material with tenacity ranging from 33 to 45 grams/denier (G/d) — making it one of the strongest synthetic fibres available. UHMWPE yarn also exhibits low elongation, high abrasion resistance, chemical stability, and natural buoyancy, making it ideal for both dry and wet environments.

Its resistance to UV rays, moisture, and Mold makes UHMWPE a reliable choice for outdoor, maritime, and industrial use. The combination of light weight, exceptional strength, and long-lasting durability helps manufacturers reduce product weight, increase safety margins, and extend service life.

Whether you’re manufacturing bulletproof vests, ballistic components, surgical threads, or next-generation lifting slings, Techtextile’s UHMWPE yarn, in collaboration with Webtex Taiwan, offers a future-ready solution backed by technical support, quality assurance, and regional agility.

Ballistic helmets, vests & panels built for safety without weight

Surgical sutures and orthopaedic implants with high biocompatibility

High dexterity gloves used in industrial and factory safety

Puncture-resistant midsoles & lightweight outsoles in hiking/utility shoes

Flexible yet strong yarns used in medical braces and mobility supports

Ballistic helmets, vests & panels built for safety without weight

Surgical sutures and orthopaedic implants with high biocompatibility

High dexterity gloves used in industrial and factory safety

Puncture-resistant midsoles & lightweight outsoles in hiking/utility shoes

Flexible yet strong yarns used in medical braces and mobility supports

Synthetic winch ropes replacing steel in heavy-duty equipment

Lightweight, high-strength UHMWPE slings used in construction & mining

Mooring lines and winch ropes trusted in harsh maritime environments

Deepwater mooring lines & cable strength members in wind and solar installations

Synthetic winch ropes replacing steel in heavy-duty equipment

Lightweight, high-strength UHMWPE slings used in construction & mining

Mooring lines and winch ropes trusted in harsh maritime environments

Deepwater mooring lines & cable strength members in wind and solar installations

Used in ballistic plates, helmets & lightweight protection panels

Long-lasting, high-strength yarns for surgical repair and internal stitching

UHMWPE-blended textiles for slash-proof clothing and workwear

Reinforced backpacks, tent fabric & gear for mountaineering or survival

Used in ballistic plates, helmets & lightweight protection panels

Long-lasting, high-strength yarns for surgical repair and internal stitching

UHMWPE-blended textiles for slash-proof clothing and workwear

Reinforced backpacks, tent fabric & gear for mountaineering or survival

Lightweight, durable performance for climbing, kiting & adventure

UHMWPE webbing for bags, luggage & outdoor gear

High-tensile suspension lines in parachutes and tether systems

Tow ropes, seatbelt reinforcements, and impact shields in vehicles

Lightweight, durable performance for climbing, kiting & adventure

UHMWPE webbing for bags, luggage & outdoor gear

High-tensile suspension lines in parachutes and tether systems

Tow ropes, seatbelt reinforcements, and impact shields in vehicles

Ballistic helmets, vests & panels built for safety without weight

Surgical sutures and orthopaedic implants with high biocompatibility

High dexterity gloves used in industrial and factory safety

Puncture-resistant midsoles & lightweight outsoles in hiking/utility shoes

Flexible yet strong yarns used in medical braces and mobility supports

Synthetic winch ropes replacing steel in heavy-duty equipment

Lightweight, high-strength UHMWPE slings used in construction & mining

Mooring lines and winch ropes trusted in harsh maritime environments

Deepwater mooring lines & cable strength members in wind and solar installations

Used in ballistic plates, helmets & lightweight protection panels

Long-lasting, high-strength yarns for surgical repair and internal stitching

UHMWPE-blended textiles for slash-proof clothing and workwear

Reinforced backpacks, tent fabric & gear for mountaineering or survival

Lightweight, durable performance for climbing, kiting & adventure

UHMWPE webbing for bags, luggage & outdoor gear

High-tensile suspension lines in parachutes and tether systems

Tow ropes, seatbelt reinforcements, and impact shields in vehicles

Ballistic helmets, vests & panels built for safety without weight

Surgical sutures and orthopaedic implants with high biocompatibility

High dexterity gloves used in industrial and factory safety

Puncture-resistant midsoles & lightweight outsoles in hiking/utility shoes

Flexible yet strong yarns used in medical braces and mobility supports

Synthetic winch ropes replacing steel in heavy-duty equipment

Lightweight, high-strength UHMWPE slings used in construction & mining

Mooring lines and winch ropes trusted in harsh maritime environments

Deepwater mooring lines & cable strength members in wind and solar installations

Used in ballistic plates, helmets & lightweight protection panels

Long-lasting, high-strength yarns for surgical repair and internal stitching

UHMWPE-blended textiles for slash-proof clothing and workwear

Reinforced backpacks, tent fabric & gear for mountaineering or survival

Lightweight, durable performance for climbing, kiting & adventure

UHMWPE webbing for bags, luggage & outdoor gear

High-tensile suspension lines in parachutes and tether systems

Tow ropes, seatbelt reinforcements, and impact shields in vehicles